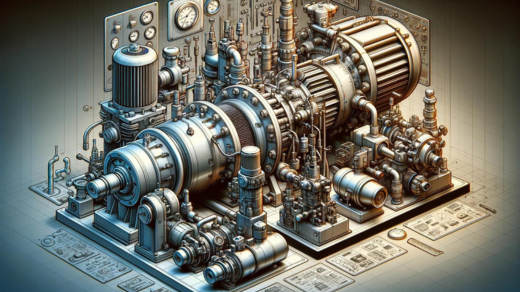

Oil vacuum pumps are indispensable tools across various industries, playing a critical role in creating vacuums for different applications. Among the different types available, rotary vane vacuum pump stand out for their efficiency and reliability.

Understanding Rotary Vane Vacuum Pumps

A rotary vane vacuum pump operates by using vanes mounted on a rotor to create a vacuum through rotation within an oil-filled cavity. This mechanism makes them highly effective for numerous industrial processes requiring precise vacuum levels.

Advantages of Oil Vacuum Pumps

Oil vacuum pumps offer several advantages. They are robust, capable of handling continuous operation with minimal maintenance requirements. Their design ensures consistent performance over extended periods, making them ideal for demanding applications.

Applications of Oil Vacuum Pumps

The versatility of oil Vacuum Pumps makes them suitable for a wide range of applications. Industries such as automotive, pharmaceuticals, food processing, and electronics rely on these pumps for tasks ranging from packaging and degassing to material handling and laboratory processes.

Choosing the Right Oil Vacuum Pump

Selecting the appropriate oil vacuum pump depends on factors such as required vacuum level, flow rate, and operating conditions. Understanding the specific needs of your application is crucial to selecting the most suitable pump.

Maintenance of Rotary Vane Vacuum Pumps

Proper maintenance is essential to ensure optimal performance and longevity of rotary vane vacuum pumps. Regular oil changes, inspection of seals and valves, and monitoring for any unusual noises or vibrations are essential practices to uphold.

Energy Efficiency Considerations

Efficiency is a key consideration in industrial operations. Modern oil vacuum pumps incorporate features aimed at reducing energy consumption without compromising performance. Choosing energy-efficient models can lead to significant cost savings over time.

Safety Precautions

Safety should always be a priority when working with vacuum systems. Proper installation, adherence to manufacturer guidelines, and regular inspections help mitigate risks associated with oil vacuum pumps.

Environmental Impact

Companies like Becker International prioritize environmental sustainability in their product design and manufacturing processes. Utilizing advanced technologies, they develop oil vacuum pumps that minimize environmental impact through efficient operation and reduced emissions.

Innovations in Vacuum Pump Technology

The field of vacuum pump technology is continually evolving, with manufacturers like Becker International leading the way in innovation. Advancements such as improved materials, enhanced sealing techniques, and smarter control systems contribute to the efficiency and reliability of oil vacuum pumps.

Cost-effectiveness of Oil Vacuum Pumps

While the initial investment in oil vacuum pumps may seem significant, their long-term cost-effectiveness makes them a wise choice for businesses. Reduced maintenance requirements, extended lifespan, and energy efficiency translate to lower overall operating costs.

Customization Options

Becker International offers customization options to tailor oil vacuum pumps to specific customer requirements. Whether it’s adapting the pump’s capacity, materials, or control features, customization ensures optimal performance for diverse applications.

Training and Support Services

Ensuring operators are proficient in the operation and maintenance of oil vacuum pumps is crucial for maximizing productivity and safety. Becker International provides comprehensive training and support services to empower customers with the knowledge and skills needed to effectively manage their vacuum systems.

Global Reach

With a presence in numerous countries, Becker International serves a diverse clientele with its range of oil vacuum pumps. Their commitment to quality and customer satisfaction has earned them a reputation as a trusted provider in the industry.

Industry Compliance

Becker International’s oil vacuum pumps adhere to stringent industry standards and regulations. Compliance with directives such as CE and ISO ensures that their products meet quality and safety requirements, instilling confidence in customers worldwide.

Case Studies

Real-world examples demonstrate the efficacy of oil vacuum pumps in various applications. Case studies highlight how Becker International’s solutions have helped businesses improve efficiency, reduce downtime, and achieve their operational goals.

Future Outlook

As industries continue to evolve, the demand for reliable vacuum solutions will remain strong. Becker International remains at the forefront of innovation, continuously refining their oil vacuum pumps to meet the evolving needs of customers worldwide.

In conclusion, oil vacuum pumps, particularly rotary vane vacuum pumps, are essential components in numerous industrial processes. With their efficiency, reliability, and versatility, they play a crucial role in ensuring the smooth operation of diverse applications. Becker International’s commitment to innovation and customer satisfaction makes them a preferred choice for businesses seeking high-quality vacuum solutions.