T Patti and T Profiles are essential components used in various industries, especially in construction and interior design. These components provide structural support and aesthetic finishes to various applications. This article will delve into the world of T Patti and T Profiles, covering their types, uses, benefits, and more.

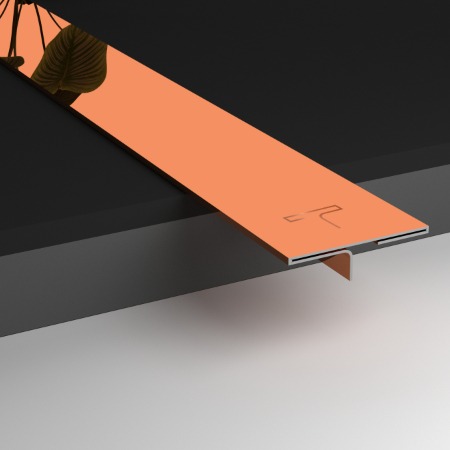

T Patti and T Profiles are crucial elements in modern construction and interior design. They are used for various purposes, including providing structural support, enhancing aesthetics, and ensuring durability. T Patti, typically made of materials like stainless steel, aluminum, or PVC, is a thin, flat strip used in various applications. T Profiles, on the other hand, have a T-shaped cross-section and are used to create strong joints and edges.

The importance of T Patti and T Profiles in construction cannot be overstated. They are used in frameworks, ceilings, partitions, and even in decorative elements. Their versatility and strength make them indispensable in both residential and commercial projects.

Types of T Patti and T Profiles

Stainless Steel T Patti

Stainless steel t patti is known for its durability and resistance to corrosion. It is widely used in both interior and exterior applications due to its strength and aesthetic appeal.

SS T Profiles

SS T Profiles, made from stainless steel, offer excellent durability and are ideal for structural applications. They are commonly used in industrial settings and construction projects that require high strength.

Aluminum T Profiles

Aluminum T Profiles are lightweight yet strong, making them suitable for a variety of applications. They are often used in areas where weight is a concern but strength cannot be compromised.

PVC T Patti

PVC T Patti is a cost-effective option that is easy to install and maintain. It is commonly used in interior applications where moisture resistance is important, such as in bathrooms and kitchens.

Sizes and Specifications

Standard Sizes

T Patti and T Profiles come in a range of standard sizes to suit different applications. Common sizes include 10mm, 12mm, and 20mm widths for T Patti and varying lengths and thicknesses for T Profiles.

Custom Sizes

Many manufacturers offer custom sizes to meet specific project requirements. Customization allows for greater flexibility in design and application.

Technical Specifications

The technical specifications of T Patti and T Profiles include details on material composition, tensile strength, and dimensional accuracy. These specifications ensure that the components meet industry standards and perform as expected.

Manufacturing Process

Raw Materials

The quality of T Patti and T Profiles begins with the selection of raw materials. Stainless steel, aluminum, and PVC are the primary materials used, each chosen for their unique properties.

Production Techniques

The manufacturing process involves cutting, shaping, and finishing the materials to create the final product. Advanced techniques such as laser cutting and CNC machining ensure precision and consistency.

Quality Control

Quality control is a critical aspect of the manufacturing process. Rigorous testing and inspection are conducted to ensure that each piece meets the required standards for strength, durability, and finish.

Applications in Various Industries

Construction

In the construction industry, T Patti and T Profiles are used in frameworks, partitions, and ceilings. They provide structural support and are essential for creating stable and durable buildings.

Interior Design

Interior designers use T Patti and T Profiles to create clean lines and modern aesthetics. These components are often used in cabinetry, wall treatments, and decorative elements.

Industrial Uses

In industrial settings, T Profiles are used in machinery, shelving, and other applications where strength and precision are critical.

Benefits of Using T Patti and T Profiles

Durability

One of the primary benefits of T Patti and T Profiles is their durability. Materials like stainless steel and aluminum offer long-lasting performance and resistance to wear and tear.

Aesthetic Appeal

These components also enhance the visual appeal of projects. They provide clean lines and a polished look that is highly desirable in both residential and commercial designs.

Versatility

The versatility of T Patti and T Profiles makes them suitable for a wide range of applications. They can be used in construction, interior design, and industrial projects, providing flexibility and adaptability.

Leading Manufacturers

Top Companies

Leading manufacturers of T Patti and T Profiles include companies like Jindal Stainless, SAIL, and Tata Steel. These companies are known for their high-quality products and innovative manufacturing techniques.

Brand Comparisons

When choosing a manufacturer, it is important to compare brands based on quality, price, and customer reviews. This ensures that you get the best value for your investment.

Market Share

The market for T Patti and T Profiles is competitive, with several key players holding significant market share. Staying informed about market trends can help in making informed purchasing decisions.

Buying Guide

How to Choose the Right T Patti

When selecting T Patti, consider factors such as material, size, and intended use. Stainless steel is ideal for durability, while PVC is suitable for cost-effective and moisture-resistant applications.

Price Considerations

Price is an important factor in any purchasing decision. Compare prices from different suppliers to find the best deal without compromising on quality.

Where to Buy

T Patti and T Profiles can be purchased from specialized suppliers, hardware stores, and online marketplaces. Ensure that you buy from reputable sources to guarantee product quality.

Installation and Maintenance

Installation Tips

Proper installation is key to the performance of T Patti and T Profiles. Follow manufacturer guidelines and use the right tools to ensure a secure fit.

Maintenance Practices

Regular maintenance helps in prolonging the life of T Patti and T Profiles. Clean them regularly and check for any signs of wear or damage.

Common Issues and Solutions

Common issues include corrosion, especially in stainless steel, and wear in high-traffic areas. Address these issues promptly to maintain the integrity of the installation.

Innovations and Trends

Latest Technological Advancements

Technological advancements have led to the development of more efficient and precise manufacturing techniques. Innovations such as laser cutting and automated production lines have improved the quality and consistency of T Patti and T Profiles.

Future Trends in T Patti and T Profiles

The future of T Patti and T Profiles looks promising with trends towards sustainable materials and eco-friendly production processes. There is also a growing demand for custom solutions tailored to specific project needs.

Case Studies

Successful Projects

Case studies of successful projects demonstrate the versatility and effectiveness of T Patti and T Profiles. These examples showcase how these components can be used creatively and efficiently in various applications.

Customer Testimonials

Customer testimonials provide insights into the real-world performance of T Patti and T Profiles. Positive feedback from satisfied customers can help in building confidence in the product.

Expert Insights

Interviews with Industry Experts

Interviews with industry experts offer valuable insights into the latest trends and best practices. These professionals can provide tips and advice on how to get the most out of T Patti and T Profiles.

Tips from Professionals

Professional tips on installation, maintenance, and selection can help in achieving the best results. Learn from the experiences of others to avoid common pitfalls and ensure success.

T Patti and T Profiles are indispensable components in construction and interior design, offering both functional and aesthetic benefits. Understanding their types, applications, and benefits can help in making informed decisions for your projects. Stay updated with the latest trends and innovations to leverage the full potential of these versatile components.